Live productin of a lightweight bicycle crank at K in Düsseldorf

PMEfluidtec presents the live production of a lightweight bicycle crank at K in Düsseldorf :

The hollow component, weighing approximately 200 grams, is made from PA6 ICF15, a thermoplastic reinforced with 15% recycled carbon fibre, which offers superior mechanical strength, high rigidity and improved heat resistance compared to standard PA6.

Visit our stand at K and experience PMEfluidtec’s state-of-the-art water injection technology live.

The partners PME and BOLE show at Fakuma 2024 how WIT-Technology conquers the bicycle sector

Together with its partner KraussMaffei, PME is showing a revolutionary children's bike at Fakuma.

PME's water injection technology (WIT) is conquering an industry in which aluminium has previously set the tone, namely the bicycle sector. On the new li:on bike of former professional cyclists Marcel Kittel and Tony Martin, the frame and fork are made using PME's WIT process:

- Frame and fork made from high-performance polymer and 40 per cent recycled carbon fibres.

- 67% less emissions compared to aluminium

- Zero waste thanks to mass back-pressure method in the WIT process

- Made in Germany

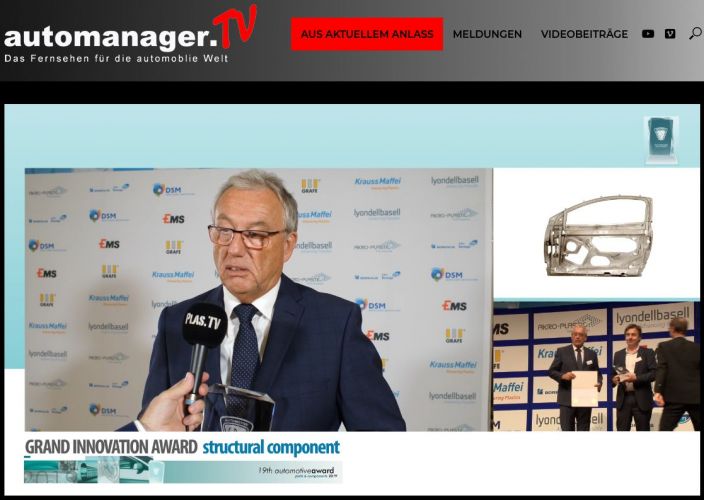

Grand Innovation Award

automanager.tv

Best-Of, Automobilkongress Zwickau - Video

For the presentation of the

Grand Innovation Award

with the long fibre material

to the company PME-Fluidtec